The following are a few signs that suggest that your inverter might need professional assistance straight away. If you get a low battery voltage, overloads and output short circuit reading on your inverter, you might want to call a technician to have it checked.

Unusual Noises Emanating from the Inverter

Common Sources of Noise in Inverters

While working an inverter might make sounds, which are common in an inverter, this is because of its parts. These sounds can be quiet humming, buzzing or clicking sounds. For standard operation, a hum that continuously is quite normal and stems from the transformer or the cooling fans working.

If you hear clicking noises, though, that may mean relays are there to switch, which could be normal during power sort changes. However, an out-of-control establishment or uneven noise levels might be indicative of a problem, for example, totally free parts, broken internal circuits, or damaged fans.

How Persistent Noise Can Indicate Internal Issues

Repeated unexpected sounds are often an indication of greater mechanical or electrical issues with the inverter. One example is a loud squealing noise, which may indicate failing, strained capacitors on the verge of failure.

Conversely, scraping sounds could mean some cooling fans are past their durability, replacing them promptly will ensure that the system does not overheat. Ignoring these signals leads to operational dysfunction or a total breakdown of the system.

Fluctuations in Power Output

Identifying Irregularities in Power Supply

When connecting devices to an inverter, if you find, for example, lights flickering or other devices unexpectedly shutting down, that means there are power fluctuations on the inverter side. Such irregularities may also be present in the form of voltage drops or spikes that will slowly destroy your more delicate equipment.

Potential Causes of Power Fluctuations in Inverters

There are a few obstacles that are the reason for inconstant power output. One of these is battery degradation, which decreases the capacity of the system to store and discharge energy. Another possibility is that the inverter setup may have faulty wiring or loose connections, hindering the power flow.

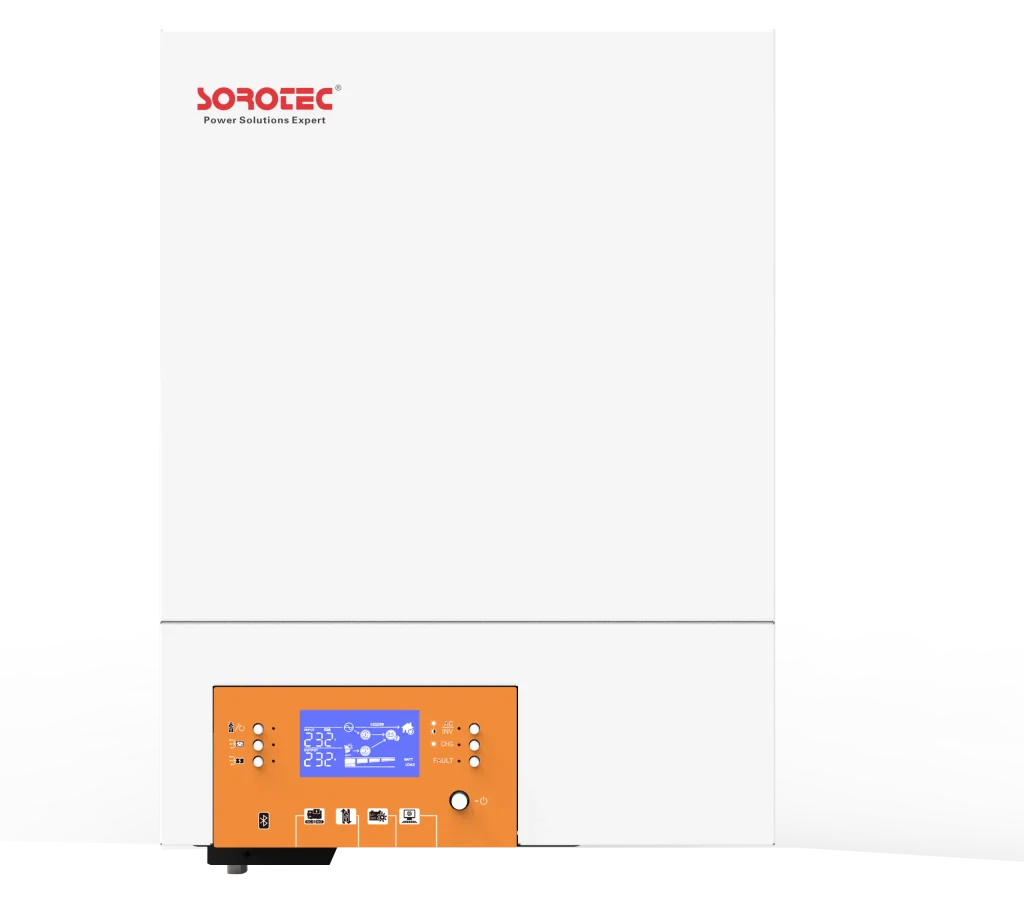

SOROTEC Solutions for Stable and Reliable Power Output

If you are after reliable power delivery, check out SOROTEC offering future-proof inverters with advanced technology. They manufacture their products in a manner as to provide the power supply to their customers even in difficult times. SOROTEC inverters are designed to minimize power interruptions and protect your connected devices with features like smart load management and high-efficiency circuits.

Overheating Issues During Operation

Signs Your Inverter is Overheating

An inverter can stop functioning properly if it overheats, and overheating is a serious matter. For example, visible signs consist of excessive heat coming out of the panel surface, working frequently, thermal protection switching the unit off, or any high-temperature error codes on its display panel.

The obvious signs are the blasted heat coming out of the surface of the unit, constant shutdowns as thermal protection activates, or errors on the interface panel from the machine about high temperatures.

Factors Leading to Thermal Overload in Inverters

Blocked pathways of ventilation inhibit appropriate airflow through the cooling unit causing thermal overload in the majority of cases. This problem is further complicated when dirt settles on the heat sink or fans, making them less efficient.

Another problem that can lead to overheating is running an inverter at full capacity very often without taking breaks. Using an inverter continuously at or near its rated capacity will also cause overheating.

Frequent Error Codes or Alarms Displayed on the Inverter Panel

Decoding Common Error Messages on Inverter Panels

The first indication of an inverter malfunction can often be an error code or alarm that is showing on the inverter. These messages are designed to notify you of particular problems such as overloading, overheating or battery issues. An “E01” might be an indicator of an overload condition and an “E02” of low battery voltage, for example.

This type of warning becomes vital to detect and fix issues before they turn into worse problems. With a little research on your inverter model and by checking your user manual regularly, you will know how to read these codes.

When Frequent Alarms Signal a Need for Repair or Replacement

Alerts or errors that appear again and again should not be neglected, because it may imply that there are underlying issues that require urgent resolution. Constant alerts for battery issues may indicate the battery is no longer meeting the specifications of the inverter.

Likewise, consistent warnings about overheating might suggest that internal cooling systems are breaking down. Likewise, if you get frequent overheating alerts, then your internal cooling mechanisms may not be working.

SOROTEC’s Intelligent Monitoring Features to Prevent Failures

They use advanced diagnostic systems built into SOROTEC inverters to ensure up-time and prevent potential failures before they occur. With their smart monitoring capabilities, users get notified in real-time and can early detect any anomalies in system performance. SOROTEC’s products have passed the international certificates.

From automatic warnings about overloading and thermal stress to the analysis of life, these inverters ensure that your operations stay running while maximizing your equipment’s lifetime.

Reduced Battery Efficiency or Rapid Discharge Rates

How an Inefficient Inverter Affects Battery Performance

A poor-quality inverter can greatly affect the performance of the battery by consuming too much current during its operation or improperly regulating the energy loads.

Decreased storage capacity and shorter service life This loss of energy speeds up the degradation of the batteries. As time goes on, you may feel the need to recharge your batteries more and more often or find that they won’t hold a charge at all.

Diagnosing Battery-Related Issues Linked to the Inverter System

Next, the first step in identifying if your inverter is indeed causing battery-related issues is to check the system voltage and load management settings for your inverter.

Deviations in these values often indicate internal faults in the inverter circuit. Also, check that the inverter connections to the battery terminals are free of corrosion/looseness as this interrupts power and increases discharge rates.

Battery-Compatible SOROTEC Models for Optimal Performance

To get the best out of SOROTEC inverters, please check their special models for different types of batteries, which easily integrate with your inverter. This adaptive charging algorithm not only charges the batteries but also stores energy as per your need, making the inverter efficient and prolonging the battery life that the inverter is powering. You can click here to know its cases.

FAQs

Q1. How can I prevent frequent error codes from appearing on my inverter panel?

A: Ensure proper maintenance by cleaning components regularly, checking connections for looseness, and avoiding overloading the system beyond its rated capacity.

Q2. What steps should I take if my inverter frequently overheats?

A: Place your inverter in a well-ventilated area away from direct sunlight, clean dust off cooling fans periodically, and reduce operational loads during peak usage hours.

Q3. Is it better to repair or replace an old inverter showing signs of inefficiency?

A: If repair costs exceed 50% of a new unit’s price or if the unit lacks modern features like intelligent monitoring systems offered by brands such as SOROTEC, replacement is often more cost-effective.